|

| The Type2b 'Transporter' and period 70's hottie. |

- They're historically cheap to buy

- They're of a very, very simple design

- Their simplicity belies the level of engineering that went into them. And every doofus with a wrench thinks he can improve on it.

But when it comes to conversions, well...take the normal VW owner's blind tinkering and turn the damnfoolishness up to 11. That's not to say that there aren't some beautiful conversions out there. There are. And the engineering challenge of stuffing an engine into a vehicle that was never remotely designed for it is appealing to people who spent their childhood taking things apart to see how they worked (regardless of whether they could get them to work after they were put back together.) But adapting a diesel engine into what was a gasoline powered vehicle is easy by comparison. We're talking about vehicles which have no place to put a radiator, a rather important lack.

Some of the 'conversion-perversions' are done as entertainment while consuming substantial amounts of beer. Some are 'drive-thru' conversions, where the vehicle is taken to a custom shop and money is sprayed at it until it runs. And some are intellectual exercises, where time, expense, and skull-sweat are the goal and the conversion of the vehicle is just the handy excuse to stave off boredom.

My goal is 'none of the above.' I have an engineer's mind without a mechanical engineer's training. My target vehicle is a 1977 7 passenger Transporter (aka Bus-bus, aka 'Ferdinand the Bulli') that has sat in a downstate Delaware barn for a dozen years before being purchased and relocated to South Central NJ. The vehicle was originally a Champagne Edition 1 which included some uprated upholstery as well as a gas fired cab heater and an uprated alternator to drive it. (The alterations to the body to support these features may eventually come in handy.)

I have almost a quarter century of experience with VWs, having owned most of the air-cooled models, installed and rebuilt my own engines, and having built a show winning 'reference restoration' 1972 VW Super Beetle (1302 model.) I've driven cross country three times in VWs, including solo jaunts in a 1971 8 passenger bus. Cars and I go way back. So when I sold the Super Beetle to a collector after its restoration was complete, I decided that a Bus for the family would be enjoyable. And certainly roomier than Beetle, which proved to be too cramped for my children.

I have almost a quarter century of experience with VWs, having owned most of the air-cooled models, installed and rebuilt my own engines, and having built a show winning 'reference restoration' 1972 VW Super Beetle (1302 model.) I've driven cross country three times in VWs, including solo jaunts in a 1971 8 passenger bus. Cars and I go way back. So when I sold the Super Beetle to a collector after its restoration was complete, I decided that a Bus for the family would be enjoyable. And certainly roomier than Beetle, which proved to be too cramped for my children.

|

| The daughter examines the bus, fresh from the barn. |

I spent from October 2010 to January 2011 studying the state of parts availability for the VW Bus in the USA. It isn't nearly as rich as it was 5 years ago. There are now only 3-5 engine builders competent to rebuild the Type4 engine used in the vehicles from 1972-1979. Because of the limited manufacturing run of the engine, consumables (like exhaust, emissions components, Fuel Injection components) are becoming scarce or are available only as rebuilds, with a fraction of the lifespan of the original.There are some attempts by enthusiasts to do limited manufacturing runs of some components to keep their rig alive, and I fully support them. These enthusiasts are doing it 'for the love,' which is good, because there is no faster way to lose your shirt than to labor under the delusion that VW owners are anything but cheapskates and no matter how clever your 'replacement parts' fabrication is, you're likely going to lose money on the deal.

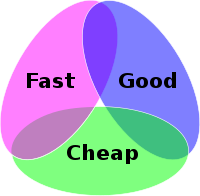

That said, there is a breed of cat that will pay a reasonable amount and then chip in his own sweat equity to the cost of the product. That's the rational DIY guy. That's me. In my day job, I constantly have to weigh compromises between 'build,' 'buy,' and 'outsource' (e.g. pay someone else to build something custom just for my company.') This is all in the hazy realm of software and hardware for high performance computing. And the triangle at the right is the balancing act that must always occur. Note that at no point do all of the Venn Diagram areas overlap each other. One of the three is always compromised in achieving the other two.

So I'm going to take what I know about the 'iron triangle' of project management, add what I know about VWs, and then attempt to work the project of putting a Subaru power plant into my VW bay window Bus. Not just because I want a solution that will insulate me from constant fiddling with the engine to keep it running or inspected, but as a 'worked example' for others to follow. Partly

There have been some great examples by people intending to do the same thing: show their work. The difference with this is that I'm going to document every decision along the way showing how I arrived at my conclusions, why I think they're the best solution for the general user who wants to DRIVE their beloved VW, and then how I accomplish it using the experience and knowledge of others (outsource), my own problem solving (build), and the engineering that others have already done (buy.) I haven't set a budget yet, but I intend to soon. My intent is to pull the complete conversion in BELOW the cost of a single reputable Type4 engine rebuild (about $3500 and good for about 80-100k miles.)

As a final pièce de résistance, I intend to perform this conversion without carving on the vehicle in casual or non-reversible ways. My goal is to made more difficult by a commitment to myself that the vehicle be able to return to a factory engine configuration without having to reconstruct the wiring harness or back half of the vehicle. Old engine out, any connectivity to the existing body, transmission, electrical, etc buffered by a breakout box so that the old engine and original components can slide back in. No permanent changes.

As a final pièce de résistance, I intend to perform this conversion without carving on the vehicle in casual or non-reversible ways. My goal is to made more difficult by a commitment to myself that the vehicle be able to return to a factory engine configuration without having to reconstruct the wiring harness or back half of the vehicle. Old engine out, any connectivity to the existing body, transmission, electrical, etc buffered by a breakout box so that the old engine and original components can slide back in. No permanent changes.

Vorwärts!

No comments:

Post a Comment